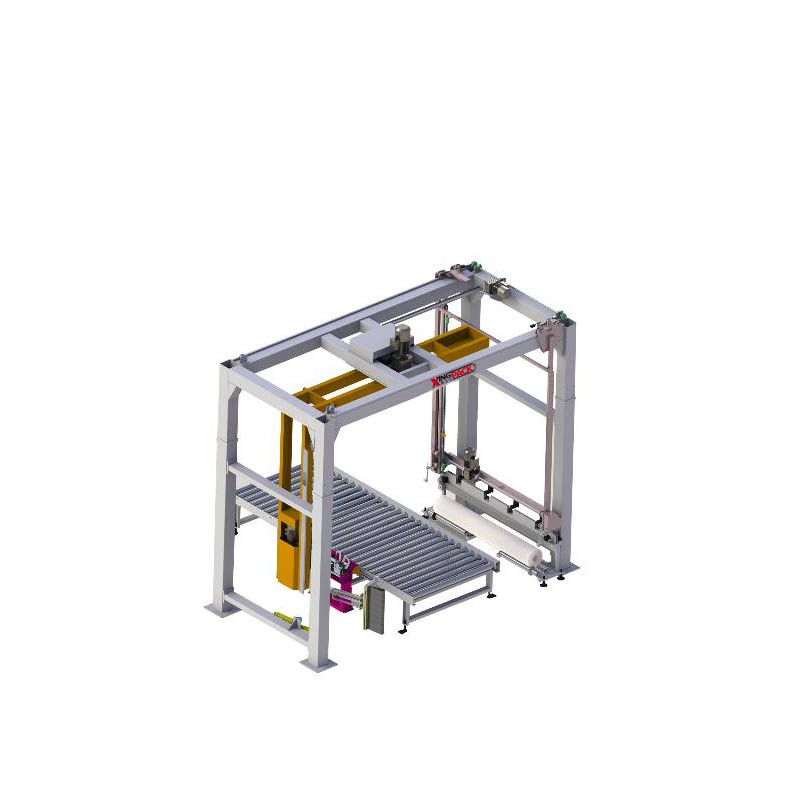

Rotary Arm Pallet Wrapper

Rotary Arm Pallet Wrapper

Rotary Arm Pallet Wrapping Machine is used the wrap the full pallet by film stretching, the pallet is stopped and the wrapping arm will rotate to stretch the fillm to wrap the pallet.

The machine is optional to put the top film sheet by adding the function of top sheet dispenser.

Features:

>> This is conveyorized wrapper for automated unmanned packing lines.

>> Machine automatically senses & centerize, wraps film around, covers the top (optional function) and conveys the pallets.

>> Two working mode choices: wrapping, or wrapping with top sheet dispensing.

>> PLC controls the whole system.

>> Automatic stretch film clamp & cut, pneumatically driven.

>> Automatic film wiping device to stick film to pallets after wrapping.

>> Independent electric box with touch screen interface as standard option.

>> Film tension, turntable speed, carriage speed & conveyor speed adjustable.

>> Power stretch film carriage, ratio 250%, film savings.

>> Machine home position & film change location for easy film carriage loading.

>> Film off and film tear alarm.

>> Troubleshooting shown on the screen.