We offer home air conditioner factory turnkey solutions, including the factory plan and design, air conditioner R&D, factory machine selection, design, manufacturing, overseas installation and training.

Generally, a complete air conditioner factory includes:

Research&Development;

Metal workshop;

Painting workshop;

Plastic injection workshop;

Heat exchanger production workshop;

Cycle pipe workshop;

SKD assembly and test line workshop(air conditioner indoor unit assembly line and air conditioner outdoor unit assembly line);

Test Labs(Enthalpy difference test labs, Calorimeter Test Labs etc.) ;

Warehouse

......

Home air conditioner assembly and test line is used to produce window type, split wall mounted type, split floor standing type, split cassette type etc.

Usually the air conditioner assembly line has outdoor unit assembly line and indoor unit assembly line. If the production capacity is less than 100 sets per 8 hours, the indoor and outdoor assembly can share a same line.

1.- Assembly Lines:

2.- Vacuum Station:

Including Vacuum pumps, Vacuum Control Boxes, Vacuum Piping etc.

3.- Refrigerant Charging:

SIATAK brand Refrigerant Charging Machine is specially designed for R410a, R290/R32/R600a charging in factories. All the components are International brands.

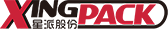

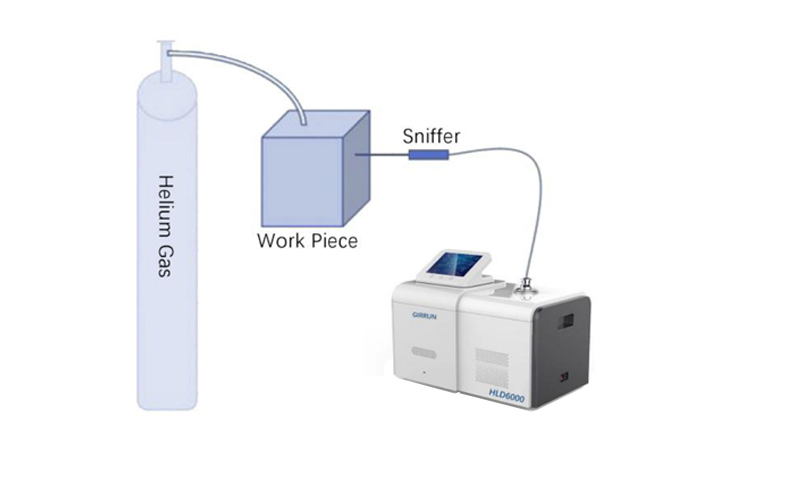

4.- Leak Test (Minor leakage detector and Mass leakage check):

Minor detector includes Halogen Leak Detector and Helium Leak Detector

5.- Air Conditioner Working Performance Test System:

Including the working performance test box, the piping system etc.

6.- Packing and Palletizing:

1.- Integrative Copper Pipe Cutting, End Forming and Pipe Bending Machine:

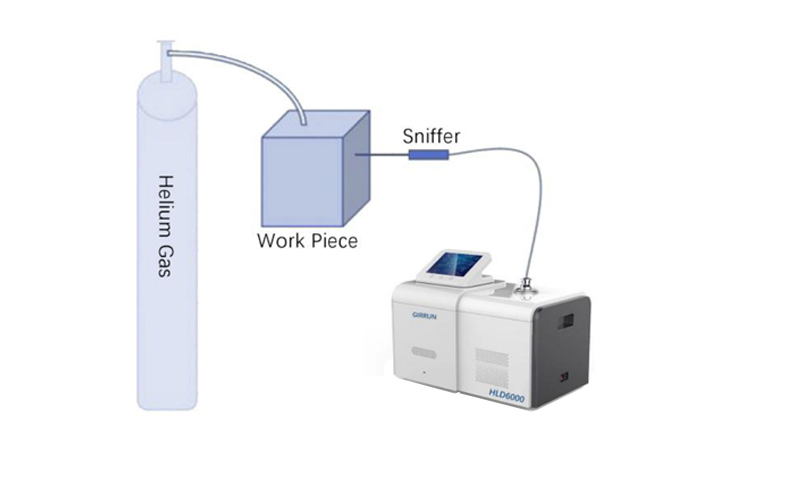

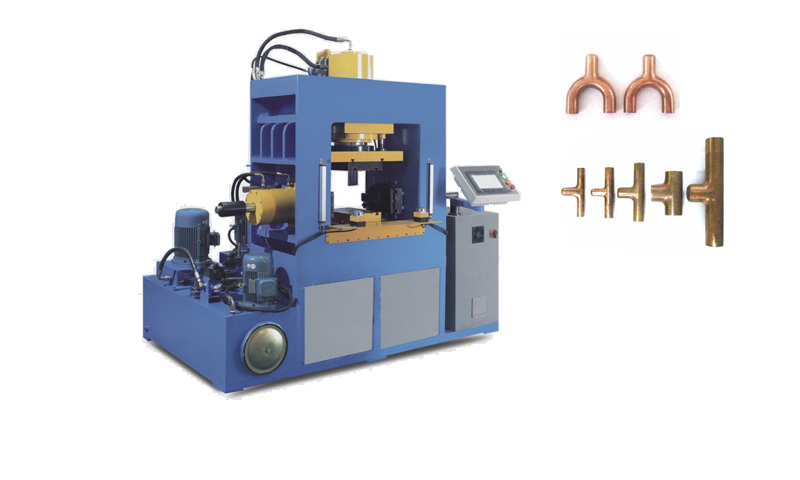

2.- Water Swelling Copper Pipe Y or T Shape Forming Machine:

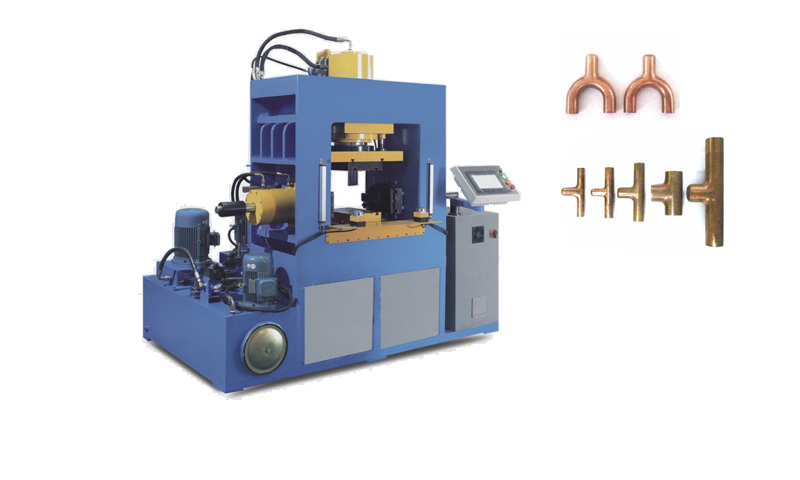

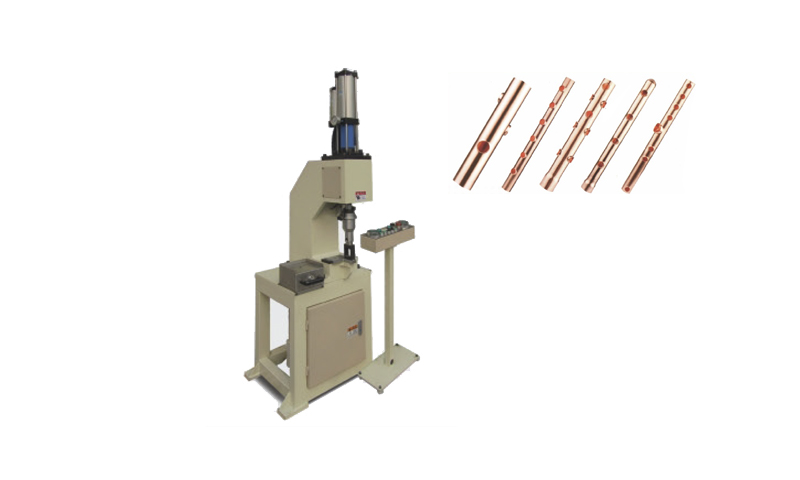

3.- Pipe Hole Drilling and Pulling Machine:

4.- Various Connectors: